Overview

For deposition capabilities please watch our short video:

VIDEO

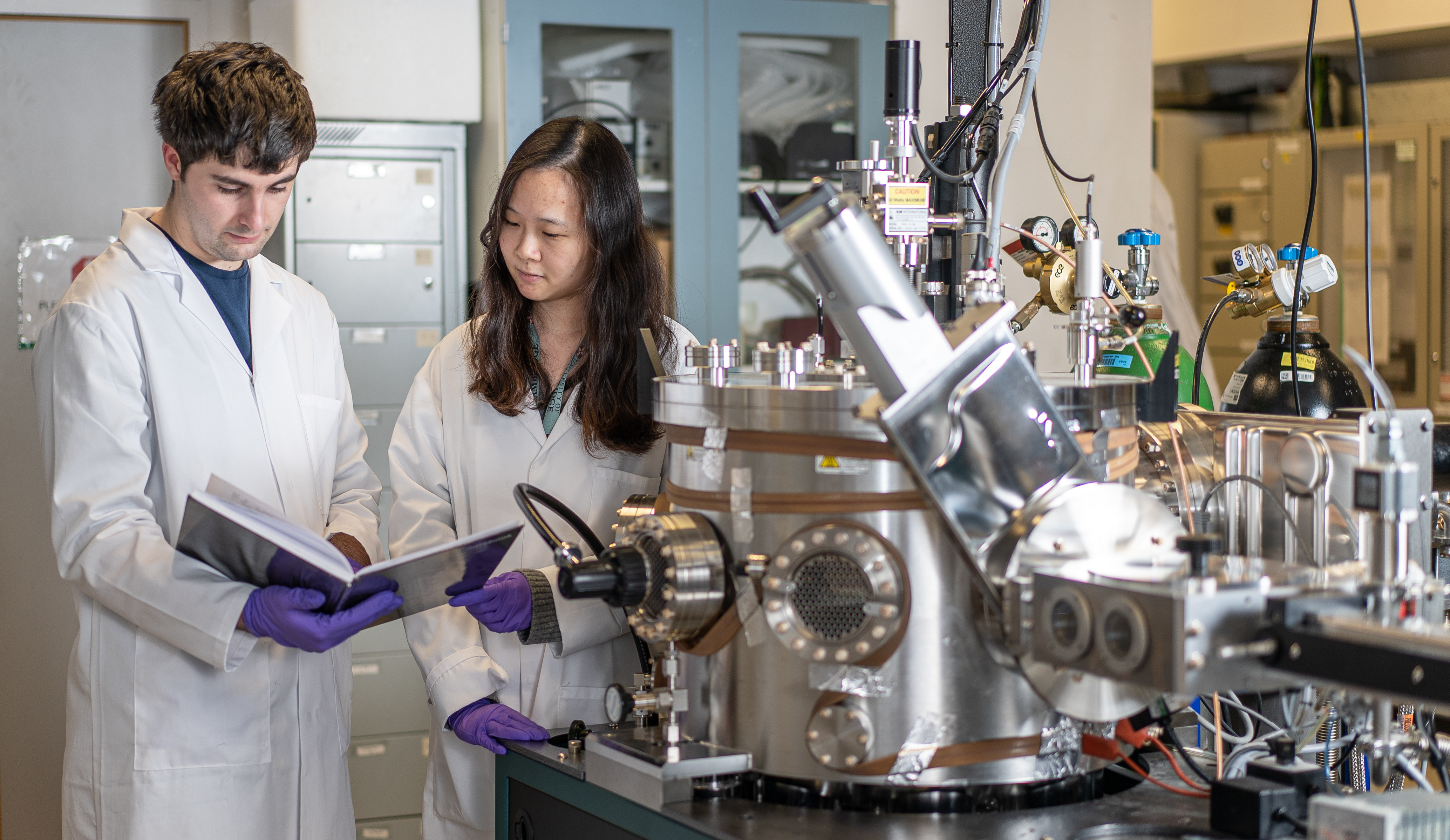

The Royce Physical Vapour Deposition and Characterisation Facility is a state-of-the-art facility for thin-film deposition and device fabrication. All equipment is shared and owned by the Department of Materials Science & Metallurgy and supported by expert Technical Staff associated with several groups across the Department including the DMG, CMP, WEMs and 2D Materials & Devices.

For more information click here or here to Book a CMP Royce Facility

For funding opportunities, please refer to the Henry Royce Institute website. Price List

Equipment

AJA Sputtering system

Highly versatile RF and DC magnetron sputtering system, very good for superconducting films such as Nb

Automated control of the sputtering process

Ultra-high vacuum system with a base pressure better than 10−8 mbar

Up to 11 target materials in one deposition

Substrate size up to 100 mm diameter

Substrate heater up to 850°C

In-situ RF plasma pre-cleaning for substrates

Quartz crystal thickness monitor

Load lock allows for high throughput of samples

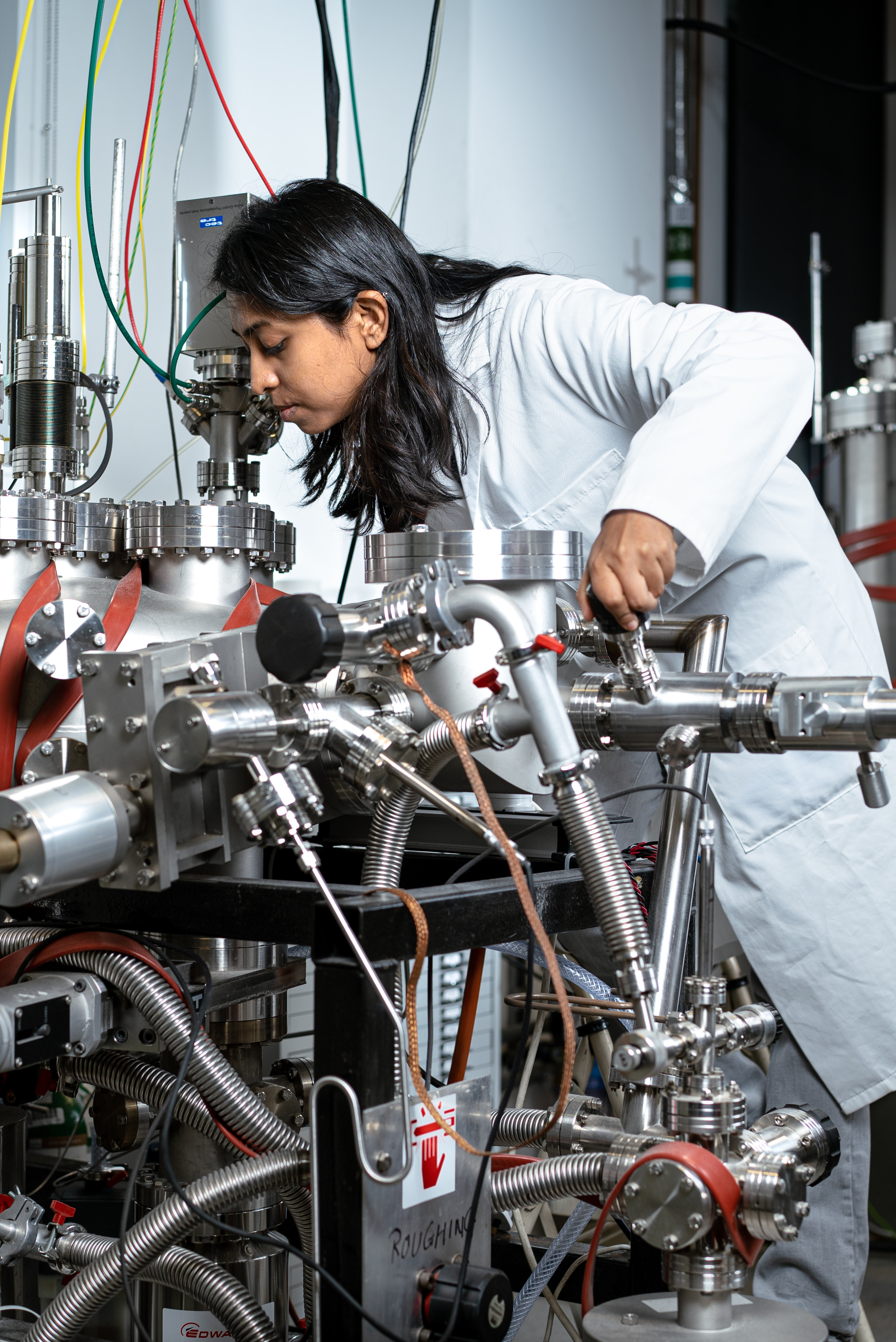

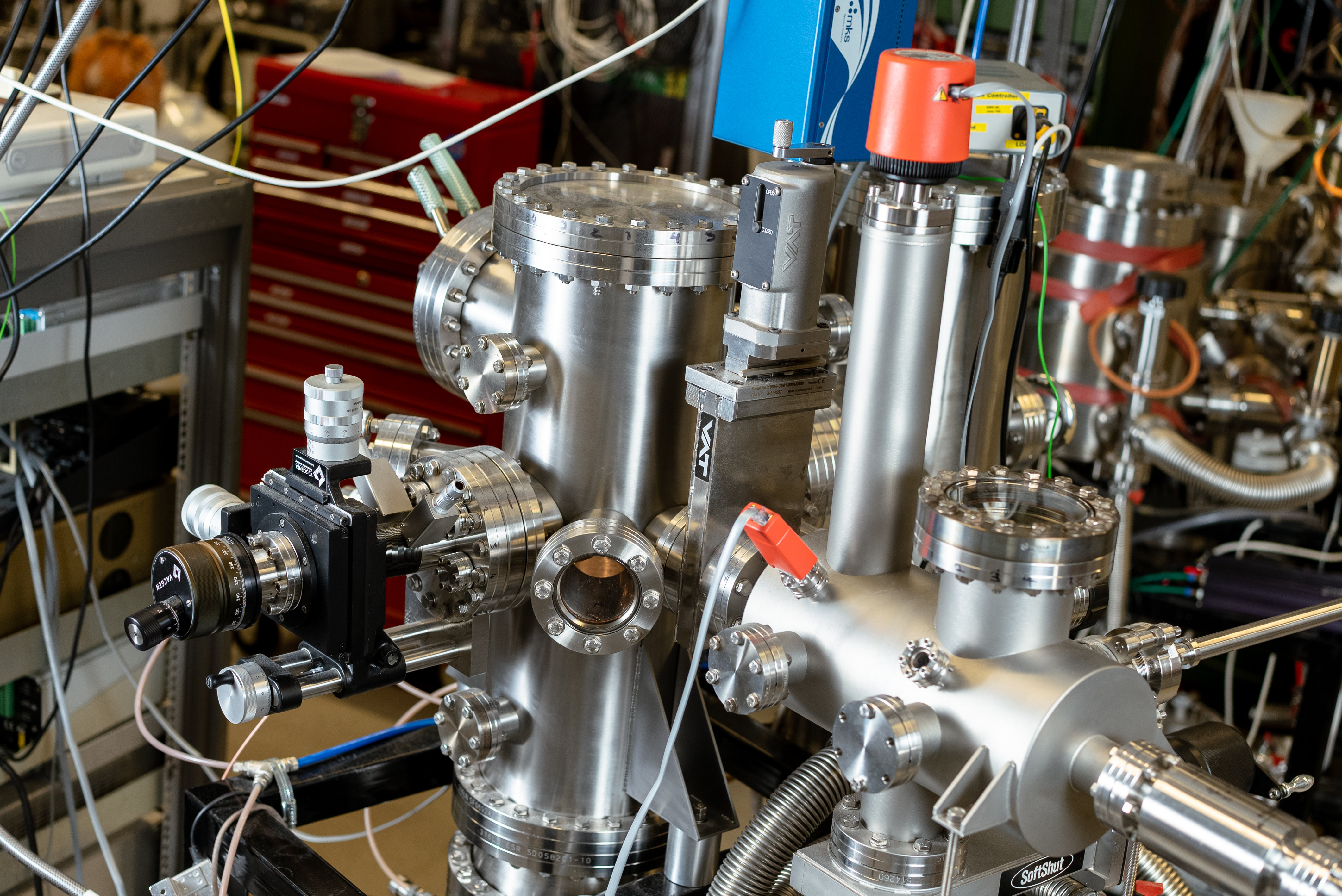

Custom sputtering systems

The facility hosts 4 custom built DC magnetron sputtering systems

Ultra-high vacuum systems up to 10−8 mbar

Up to 4 different target materials

Turntable with automated thickness control allows growth of multiple different samples in one deposition

Sample heaters up to 1100°C is possible

Reactive sputtering of nitrides and conductive oxides is possible

Highly customisable systems

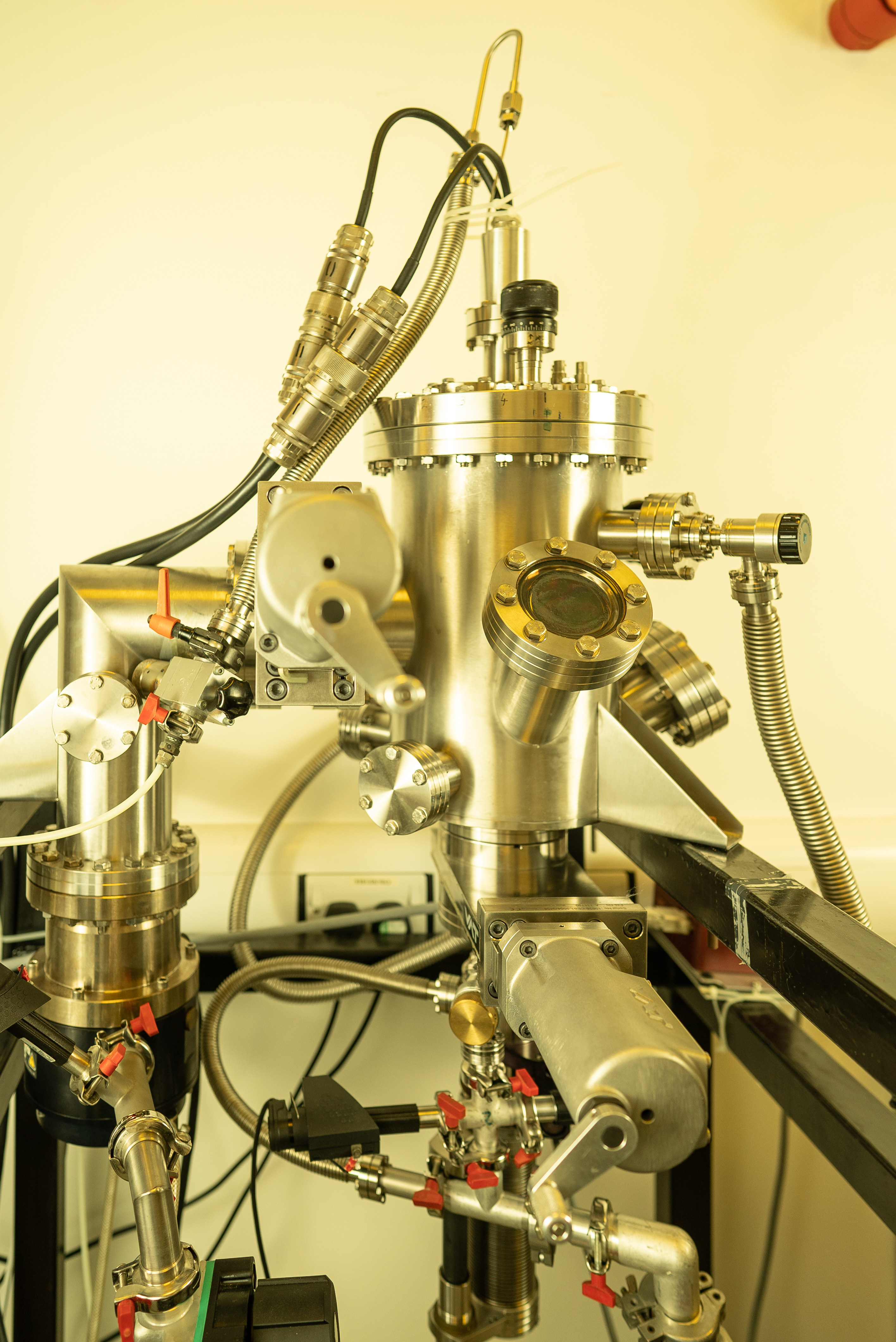

Electron beam evaporator

Can grow high purity polycrystalline metallic films such as Au, Nb, Pt, V, Al, and Cu

Up to 7 targets in one deposition

Can grow at room temperature or liquid nitrogen temperature

Can achieve a vacuum level of 10−8 mbar

Quartz crystal thickness monitor

Load lock allows for high sample throughput

Argon ion miller

The argon ion miller allows for anisotropic and non-selective etching of devices.

Suitable for metallic or insulating materials.

Atomic force microscope

A Bruker Multimode 8 with Nanoscope 5 controller.

Has several different modes of operation.

Contact, tapping and peak force modes

Standard atomic force microscopy (AFM)

Magnetic force microscopy (MFM)

Piezoelectric force microscopy (PFM)

Kelvin probe force microscopy (KPFM)

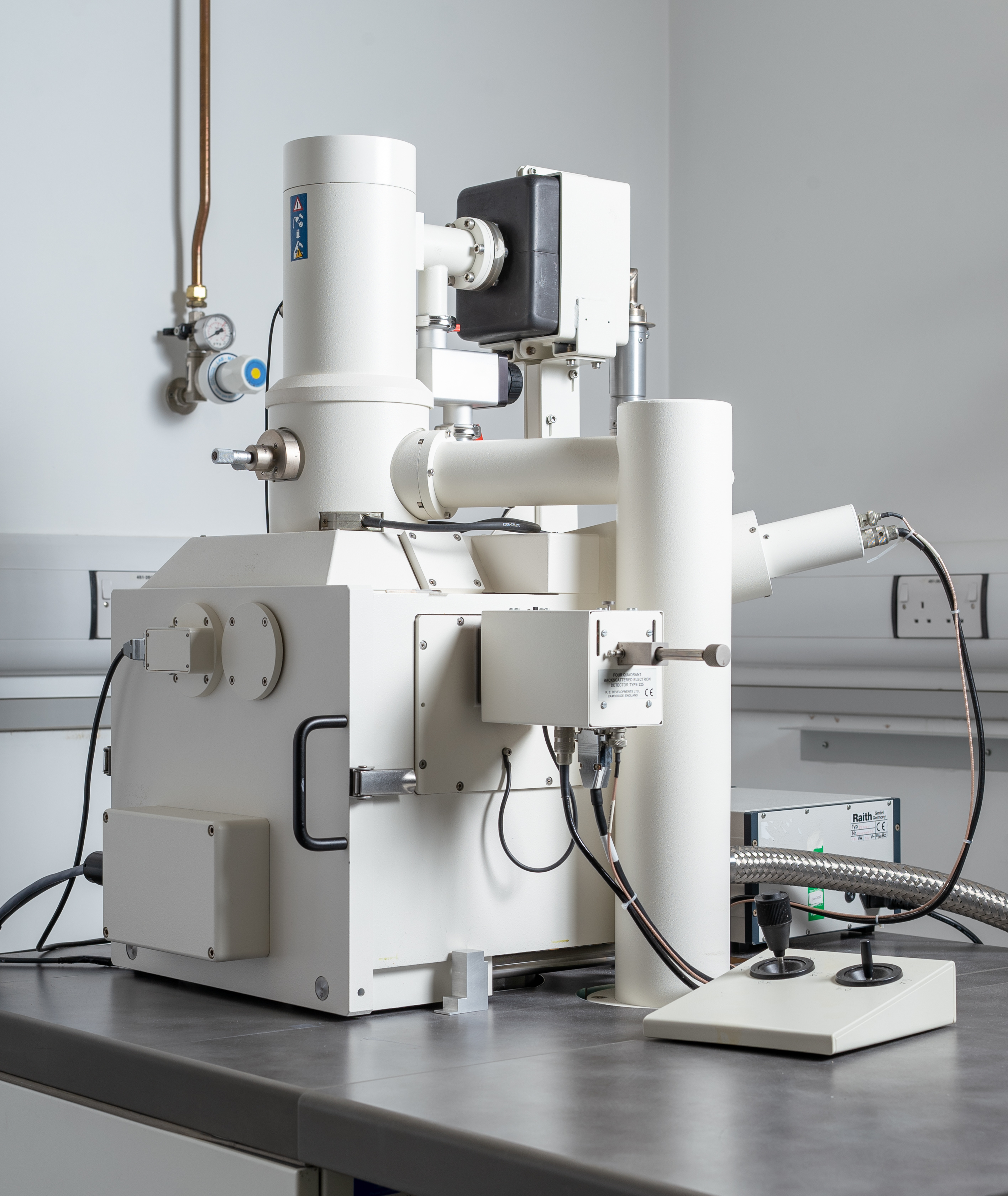

Electron-beam lithography system

LEO /ZEISS 1455VP scanning electron microscope equipped with Raith Elphy Quantum for device fabrication.

Accelerating voltages from 200 V to 30 kV

Single writefield up to 1000 μm

250 nm feature resolution exposed using a 400 μm writefield

PC-based pattern generator allow up to 63 different layers

Allows fully automated or user assisted field to field alignment

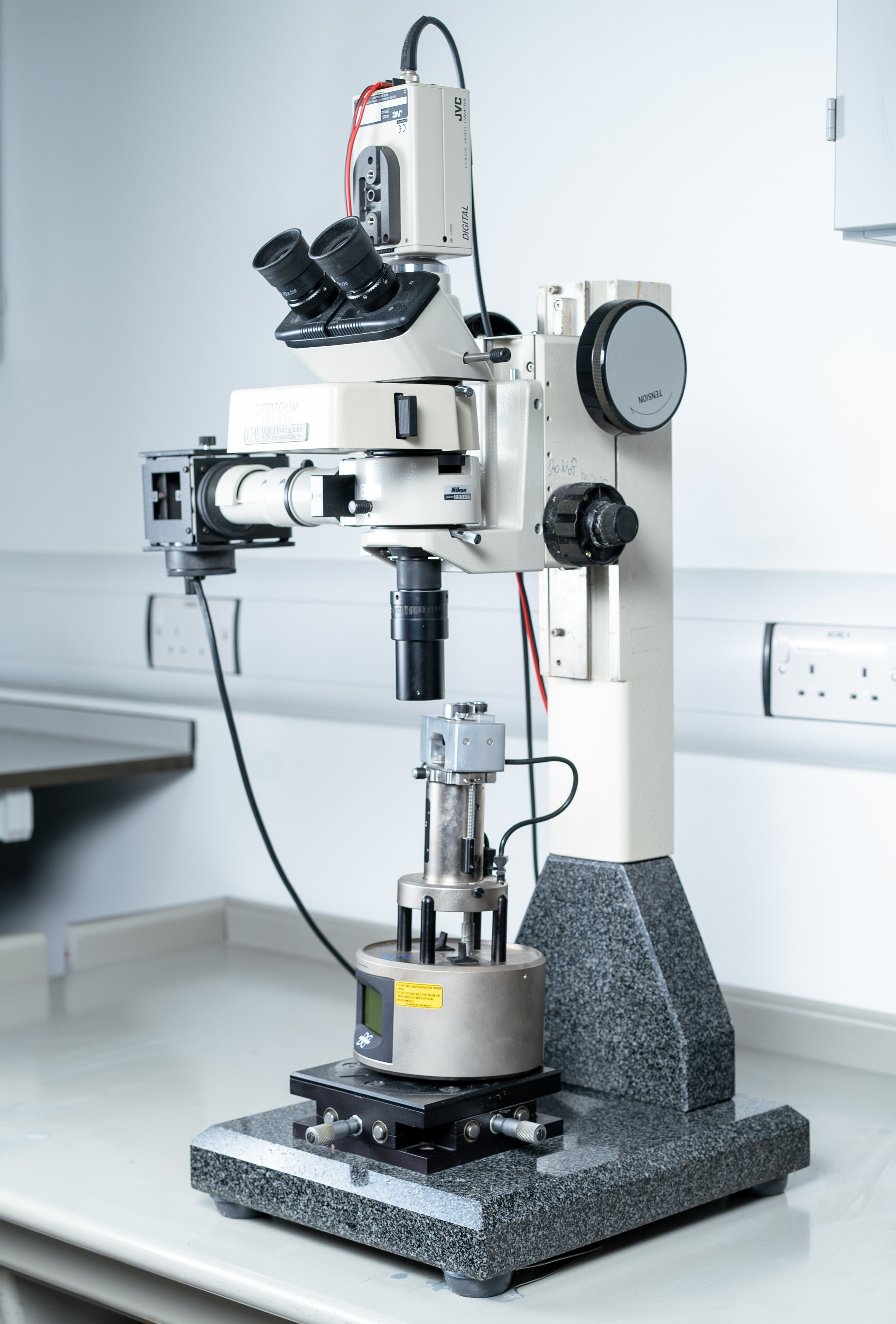

Cryogenic DC/RF Probe station

Lake Shore Cryogenics CRX-6.5K

Base temperature 12 K (2-probes) - 350 K

Maximum 5-probes (DC/RF)

Maximum sample size 51 mm (2")

Vacuum <5x10^-4 Torr

Visual System: 2.8 microns resolution